How It Works

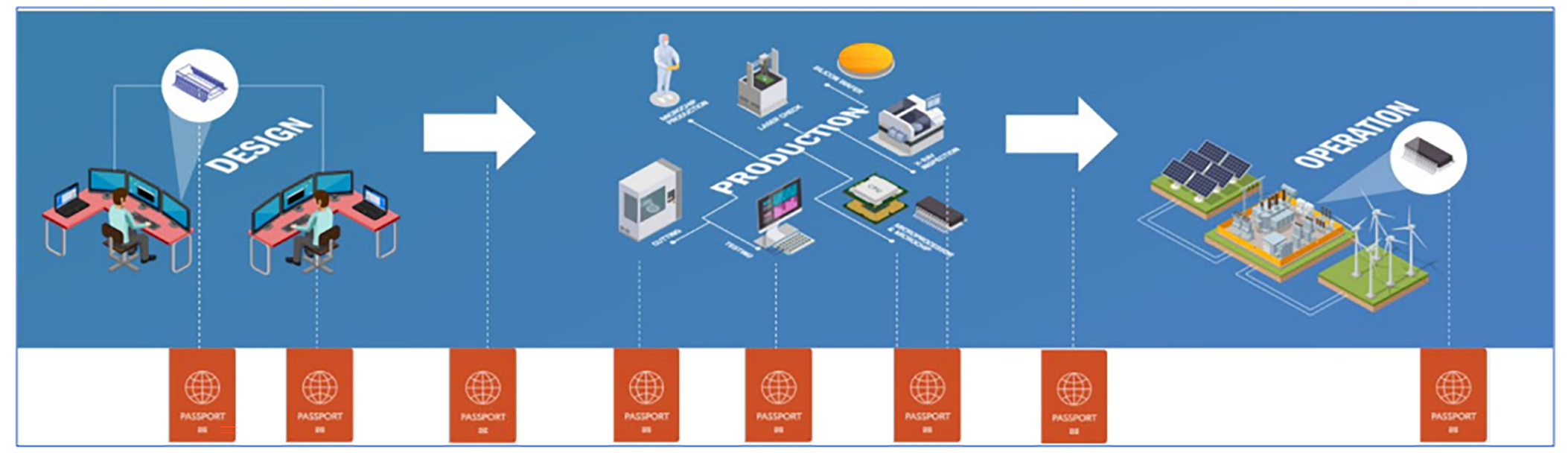

The CPP works by connecting each physical part to a digital framework that tracks every part through the supply chain and manufacturing process. Suppliers and manufacturers contribute to the passport chain as it grows, enriching the data over the lifecycle of the manufacturing process.

- Digital Identity for Parts. Each part receives a unique digital identifier, akin to a passport.

- Tracking and Verification. The digital identifier tracks the part’s origin, manufacturing process, and any changes or inspections along the way.

- Secure Data Access. Manufacturers and regulators can securely access CPP information to verify a part’s authenticity and compliance.

The Benefits

Adopting CyManII’s CPP technology offers a range of benefits that accrue over time for both individual manufacturers and the wider manufacturing community. For individual manufacturers, the CPP system:

- Meets some regulatory reporting requirements

- Furnishes data to help companies identify problems and improve efficiency

Within the larger manufacturing community, the CPP system:

- Fosters TRUST between suppliers and manufacturers

- Improves VISIBILITY across supply chains

- Encourages COLLABORATION between companies and across sectors

CyManII is already working with GE Vernova, a large original equipment manufacturer (OEM) in the energy sector, and several small-to-medium manufacturers (SMMs) to implement a CPP pilot program for industrial control system (ICS) devices.

National Impact

As the CPP system matures, U.S. manufacturing will further advance the national interest by:

- Strengthening national security by reducing the risk of faulty, tampered, or counterfeit parts in U.S. supply chains

- Strengthening U.S. global competitiveness by making U.S. manufacturing more productive, secure, and innovative

- Creating jobs by encouraging companies to build more manufacturing parts production in the United States

National Competitive Advantage

The European Union utilizes a similar, but more limited, technology called a Digital Product Passport (DPP), and China is in the process of developing its own version. CyManII’s CPP goes beyond these data models while offering full implementation and software services that provide security, integrity, and empower greater productivity.

Looking Ahead

CyManII is actively working to implement CPP pilots. Through its Industry Use Case Partnerships, CyManII is working directly with industry to implement CPP technology and enable full supply-chain transparency, optimization, and cyber-risk evaluation for an individual product, and the systems and materials involved in its manufacture.